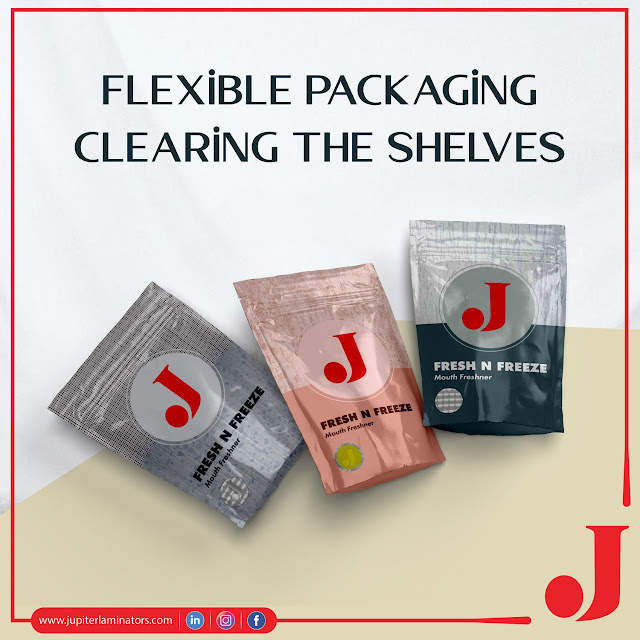

When it comes to flexible packaging, flexible packages are packages whose shape can be easily manipulated or folded. In general, these materials are made from various plastic formulations, foils, cardboard, and biopolymers. Flexible packaging is rapidly replacing the more expensive and less environmentally friendly forms of rigid packaging. With a smaller carbon footprint and lower cost than their rigid counterparts, flexible packaging materials are attractive to consumers around the world.

There

are many types of flexible packaging

materials. However, the most popular variations include shrink wrap, stretch

wrap, flex bags, roll bags, poly bags, straps, and cartons.

Flexible or rigid containers

This

type of innovative packaging offers an economical alternative to conventional

rigid packaging. With only 25% of the plastic used for its rigid counterpart,

it weighs 70% less than rigid packaging. Most product owners find it easy and

affordable to ship both domestically and internationally. It also has more

design options, including the stand-up function that offers eye-catching

printing options, billboard effect marketing, great product appeal, and space

management.

Does Flexible packaging Really Protect Your Product?

Flexible

packaging

often uses a film to provide a barrier against the light (for example, the sun's

ultraviolet rays), grease, contaminants, and most importantly, moisture and

oxygen. Each of the barrier layers is specially selected based on the physical

properties of its product. When manufacturers design a high barrier, they

calculate the OTR (Oxygen Transfer Rate) and MVTR (Moisture Vapor Transmission

Rate). The OTR and MVTR determine the amount of air or moisture that is

transferred through a specific section of film/material within 24 hours. A

high rating ensures that the product can withstand a variety of stressors and

gives it storage stability.

For instance …

The

most ideal barrier packaging has extremely low OTR and MVTR that allow little

oxygen and moisture to pass through over any length of time (the film is a good

example). It protects your product from contaminants.

Biodegradable

In

the past, most of the plastic packaging material could not be decomposed.

However, scientists recently discovered a way to add an additive to polymers

used in flexible and rigid packaging to make them biodegradable. The additive

causes decomposition to begin as soon as the materials are exposed to a large

number of germs (such as in a landfill). Materials are reduced in water and

carbon. This process usually occurs 18 months after exposure. The science

behind this allows for similar barrier properties along with durability and

stability. Innovation in this field continues to grow and will be the first

choice for packaging today and in the future.

Ready to try flexible packaging?

Is

flexible packaging a viable option for your

product? Flexible packaging companies can design

packages to meet your product's temperature requirements, size recommendations,

certification standards, and barrier properties.

0 Comments